CrystalGleam Glassware

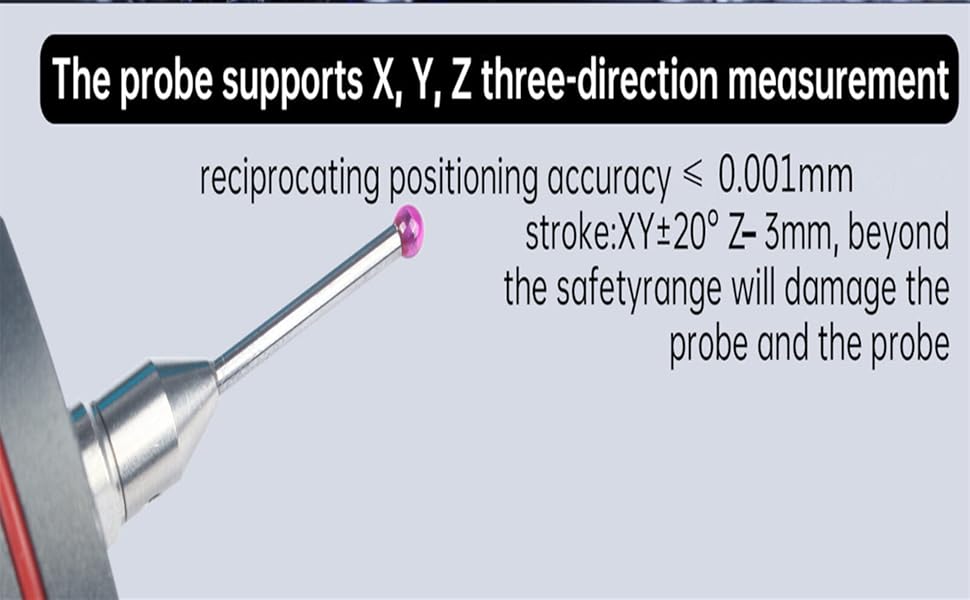

CNCTOPBAOS High Precision 3D Edge Finder 0.001mm NO,Waterproof CNC Machining Center Trigger Touch Probe,Milling Machine Automatic Find Center Position Locator,XYZ Coordinate Tool Setter Measuring+Tip

CNCTOPBAOS High Precision 3D Edge Finder 0.001mm NO,Waterproof CNC Machining Center Trigger Touch Probe,Milling Machine Automatic Find Center Position Locator,XYZ Coordinate Tool Setter Measuring+Tip

Regular price

$147.00 USD

Regular price

$147.00 USD

Sale price

$147.00 USD

Shipping calculated at checkout.

Quantity

Couldn't load pickup availability

Product description